T: +86-572-6200777

Mr. Xin: +86-17357227212

Mr. Xin: +86-17357227212

Mr.Li: +86-13706256441

Building 31, Tianneng Chain Innovation Industrial Park, Meishan Town, Changxing County, Huzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

When comparing HEPA vs ULPA filters, your choice impacts air quality, safety, and cost. HEPA filters capture at least 99.97% of particles as small as 0.3 microns, making them the preferred option for homes and industrial settings. ULPA filters go further by trapping 99.999% of even smaller particles down to 0.12 microns, reducing contamination by 40-60% in sensitive environments. Selecting the right filter is essential for maintaining safety in cleanrooms, laboratories, and manufacturing facilities. The table below highlights the differences in market share and applications between HEPA and ULPA filters:

Aspect | HEPA Filters | ULPA Filters |

|---|---|---|

Filtration Efficiency | ≥99.97% (≥0.3 microns) | ≥99.999% (≥0.12 microns) |

Main Application | Residential, Industrial | Cleanrooms, Semiconductor |

Market Share | Broad dominance | Specialized use |

HEPA filters trap 99.97% of particles that are 0.3 microns or bigger. ULPA filters trap 99.999% of particles as small as 0.12 microns. This makes ULPA filters better for places that need very clean air.HEPA filters cost less and let more air pass through. They also last longer. This makes them good for homes, hospitals, and most cleanrooms. ULPA filters cost more and let less air pass through. They need to be changed more often. They are used in stricter cleanrooms and labs.You should pick a filter based on your needs, where you use it, and your budget. Use HEPA filters for regular air cleaning. Use ULPA filters for places that need very clean air.To keep filters working well, check and change them on time. Watch for changes in pressure and leaks. This saves energy and keeps your system safe.Using pre-filters helps both HEPA and ULPA filters last longer. Pre-filters catch bigger particles first. This saves money and helps the filters work better.

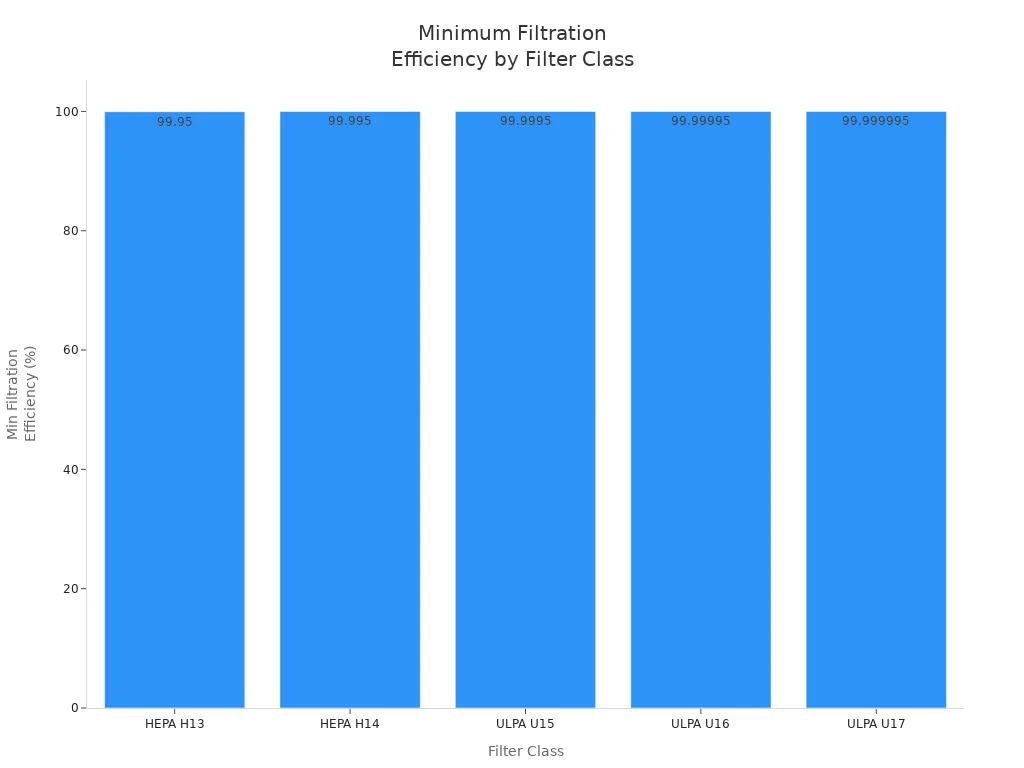

The biggest difference between HEPA and ULPA filters is how well they clean the air. HEPA filters must catch at least 99.97% of tiny particles that are 0.3 microns or bigger. ULPA filters do even better. They remove at least 99.999% of particles as small as 0.12 microns. Rules like EN 1822 and ISO 29463 set these standards. The chart below shows that higher filter classes trap more particles.

HEPA filters can trap things like dust, pollen, and some bacteria. They catch particles down to 0.3 microns. ULPA filters grab even smaller particles, down to 0.12 microns. This makes ULPA filters great for places that need very clean air. These filters are used in cleanrooms for making computer chips or medicine.

Filter Type | Particle Size Captured (microns) | Filtration Efficiency (%) | Notes |

|---|---|---|---|

HEPA | ≥ 0.3 | 99.97 | Standard for most cleanrooms and air systems |

ULPA | ≥ 0.12 | 99.999 | Used for stricter cleanroom applications |

Airflow is important when picking a filter. HEPA filters let more air move through with less effort. ULPA filters are tighter, so air has a harder time getting through. This means you might need stronger fans, which use more energy. In big air systems, ULPA filters can slow down air changes and cost more to run.

Tip: Make sure to think about both how well the filter works and how much air can move through. This helps your system work well and saves energy.

HEPA filters are cheaper than ULPA filters. ULPA filters cost about 30% more and use more energy because air moves slower through them. You might also pay more for fixing and replacing ULPA filters over time. For most uses, HEPA filters give you good cleaning and save money.

HEPA filters are found in cleanrooms rated ISO 5 to ISO 8. They are also used in hospitals, food factories, and air cleaners. ULPA filters are used in the cleanest rooms, like those for making computer chips, airplanes, or medicine. Both filters use special materials like glass fiber or membrane filter paper. You can get these from companies like MECONM. These materials help the filters work well in important places.

HEPA filters are used where air must be very clean. HEPA means high efficiency particulate air. These filters have a thick mat of fibers. The fibers catch tiny things in the air. When you use a high-efficiency particulate air filter, you can get rid of dust, pollen, mold spores, and some bacteria. The main goal is to catch particles as small as 0.3 microns. Many HEPA filters use glass fiber filter paper or membrane filter paper. This helps them work better.

You can count on HEPA filters to work well. High-efficiency particulate air filters must remove at least 99.97% of particles that are 0.3 microns or bigger. Some filters can even reach 99.997% efficiency. This means the air is much cleaner and has fewer allergens. HEPA filters trap particles in different ways, like interception and diffusion. You can trust these filters to keep your indoor air safe.

HEPA filters are found in many places. They help in homes, offices, hospitals, and labs. The table below shows where they are used and why:

Setting | Common Applications | Purpose and Benefits |

|---|---|---|

Residential | Portable air purifiers, HVAC system integration | Improve indoor air by catching dust, pollen, pet dander, and mold spores; good for people with allergies. |

Commercial | Offices, retail spaces, healthcare facilities, restaurants, hotels, food processing | Keep air clean, lower germs in the air, control smells and smoke; often used with HVAC systems in big spaces. |

Medical | Hospitals, clinics, laboratories, pharmaceutical manufacturing, veterinary hospitals | Stop germs by trapping bacteria and viruses; keep rooms sterile and lower infection risks. |

You can also find HEPA filters in airplane cabins, schools, and food plants. These filters help keep people safe from bad particles and keep places clean.

Tip: Think about the good and bad points before picking a HEPA filter.

Advantages:

Removes most things in the air, like allergens, bacteria, and viruses.

Makes air better and helps people with asthma or allergies.

Helps pets and people stay healthy.

Disadvantages:

Only catches particles, not gases or fumes.

Needs to be cleaned and changed often.

Can be loud in some machines.

Costs more than regular filters.

If you want strong high efficiency particulate air filtration, look at products from MECONM. Their HEPA filter paper uses new technology for steady, high-quality results. You can also check out membrane filter paper for special needs.

Sometimes you need the cleanest air possible. ULPA filters help with this. They are a type of ultra-low particulate air filter. ULPA filters catch very tiny particles that other filters miss. They use thick layers of glass fiber filter paper or membrane filter paper. This helps them trap particles as small as 0.12 microns. That makes them great for places where even tiny bits matter.

ULPA filters are known for being very efficient. They remove at least 99.999% of particles from the air. This is much better than regular filters. You will see ULPA filters in places that need very clean air, like ISO Class 3 or 4 cleanrooms. Their special design keeps almost all particles out. This is important for sensitive work.

ULPA filters are used in special places. They are important in cleanrooms, labs, and drug factories. These filters keep air pure for science, chemical tests, and nanotechnology. In chip factories, ULPA filters protect microchips from dust. You also find them in biosafety cabinets, laminar flow hoods, and glove boxes.

Environment/Industry | Common ULPA Filter Applications |

|---|---|

Cleanrooms and Laboratories | Keeping air clean for science and nanotechnology. |

Pharmaceutical Facilities | Making sure air is sterile in drug labs and factories. |

Semiconductor Manufacturing | Protecting microchips from dust during making. |

Laboratory Equipment | Used in biosafety cabinets, laminar flow hoods, and glove boxes for clean air. |

Note: MECONM has ULPA filter materials for advanced cleanrooms and labs.

Think about the good and bad sides before picking ULPA filters.

Aspect | Advantages | Disadvantages |

|---|---|---|

Particle Capture | Very good at catching tiny particles, great for strict cleanrooms | Lets less air through, so uses more energy |

Application | Best for places that need very clean air | Does not last as long and costs more than HEPA filters |

Cost | Gives very low particle counts | Costs more at first and needs to be replaced more often |

Energy Efficiency | Works well with pre-filters to save energy | Needs stronger fans because air moves slower |

Operational Use | Fits in laminar flow hoods, isolation rooms, and containment systems | Not the best choice for normal places that do not need super clean air |

If you need the cleanest air, ULPA filters from MECONM work well. You can also look at other filter materials like hydraulic oil filter paper for other jobs.

It is important to know how hepa and ulpa filters are different. The table below shows the main features side by side. This helps you pick the best filter for your cleanroom, lab, or HVAC system.

Feature | HEPA Filters | ULPA Filters |

|---|---|---|

Filtration Efficiency | 99.97% to 99.99% (≥0.3 microns) | 99.999% (≥0.12 microns) |

Particle Size Captured | Down to 0.3 microns | Down to 0.12 microns |

Airflow Resistance | Lower | Higher |

Cost | Lower initial and replacement cost | Up to 30% higher, more frequent replacement |

Lifespan (Cleanroom) | Up to 10 years | 7 to 8 years |

Lifespan (HVAC) | About 12 months | About 6 months |

Maintenance | Less complex, regular replacement | More frequent, requires testing |

Application Fields | Hospitals, labs, food plants, homes | Semiconductor, pharma, ISO-5 cleanrooms |

Note: MECONM New Materials has both hepa and ulpa filter materials. They offer air filter paper and membrane filter paper for all these uses.

When you look at hepa and ulpa filters, you see ulpa filters are about 10 times better at filtering. Ulpa filters catch 99.999% of tiny particles as small as 0.12 microns. Hepa filters trap 99.97% to 99.99% of particles at 0.3 microns. This means ulpa filters block even smaller things from getting into your cleanroom or lab.

But better filtering does not always mean better performance. You also need to think about airflow. Ulpa filters are thicker, so they can slow down air by 20% to 50% in systems made for hepa filters. If you want to use ulpa filters, you might need to change your system to keep the right amount of air moving. Newer systems with better fans and bigger filters can help keep airflow and filtering balanced.

In real life, like in biosafety cabinets, ulpa filters handle air changes better. Stronger air flow from above helps control particles when you move things around. This keeps your space safer, which is important in places like chip factories or medicine labs.

MECONM New Materials uses nano glass fibers and special machines to make filter materials. These materials give high filtering power and low resistance. This means you get good filtering and still have enough airflow, no matter which filter you pick.

You want your filters to last a long time, but how long they last depends on the filter type and how you use it. Hepa filters in cleanrooms can last up to 10 years. Ulpa filters usually last 7 to 8 years. In HVAC systems, hepa filters need to be changed every 12 months. Ulpa filters need to be changed every 6 months. Ulpa filters fill up faster because they catch smaller particles, so you have to change them more often.

Using pre-filters, like gradient filter paper, can help both hepa and ulpa filters last longer. Pre-filters catch bigger particles first. This means your main filter does not have to work as hard and can last longer, saving you money.

Filter Type | Typical Lifespan (Cleanroom) | Typical Lifespan (HVAC) |

|---|---|---|

HEPA | Up to 10 years | About 12 months |

ULPA | 7 to 8 years | About 6 months |

Tip: Always follow what the maker says for when to change filters. MECONM can help you set up a good maintenance plan for your system.

Taking care of your filters keeps your air clean and your system working well. For both hepa and ulpa filters, you should watch the pressure drop. When the pressure is twice what it was at the start, it is time to change the filter. This saves energy and keeps your equipment safe.

Hepa filters are easier to take care of. You just replace them and check for leaks. Ulpa filters need to be tested more often and must be put in carefully to stop leaks around the edges. In busy places, you might need to change ulpa filters every 3 to 6 months. Always look for damage, like holes or tears, and make sure the filter fits right.

Some common problems are filter leaks, having to change filters a lot, and higher energy use with ulpa filters. You can fix these problems by:

Doing regular leak tests (like DOP tests) to check for holes.

Changing filters when the pressure gets too high.

Using machines that watch airflow and pressure for you.

Planning regular checks, cleaning, and filter changes.

MECONM New Materials makes filter materials that are easy to use and take care of. Their team can help you make a plan for taking care of your filters, whether you use hepa or ulpa.

Remember: Clean filters keep you, your products, and your machines safe. Pick the right filter and keep up with care for the best results.

When you pick between HEPA and ULPA filters, think about what you need to clean from the air. Ask yourself what particles you want to remove. In hospitals or labs, you need to catch germs like bacteria and viruses. This keeps the air safe for people. In chip labs or microelectronics, you must get rid of even smaller bits. This protects delicate machines. For very clean rooms, ULPA filters are best because they trap the tiniest things. For homes, offices, or most medical places, HEPA filters usually work well.

Tip: Glass fiber filter paper helps clean air faster. If you need to filter oil or liquids, use hydraulic oil filter paper.

You also need to think about where you will use the filter. Different places have different needs for clean air. Cleanrooms and labs need filters that meet strict rules. Medical places need filters to stop germs in the air. Food factories and schools need to control dust and allergens.

Things like temperature, humidity, and chemicals can change how filters work. For example, high humidity can make some filters not work as well. High heat needs filters made from special materials like glass fiber filter paper. Chemicals can hurt some filters.

ULPA filters are thicker, so they slow down airflow by 20-50%. This means the air in a room changes less often. You need to check if your system can handle this. Always make sure your filter matches your system’s airflow and pressure needs.

How much money you have is important when picking a filter. HEPA filters cost less than ULPA filters. ULPA filters are about 36% more expensive for the same size. You also have to change ULPA filters more often, every 3 to 6 months in busy places. HEPA filters can last up to 10 years in clean rooms. ULPA filters last about 5 to 8 years.

Here is a quick look at the costs:

Filter Type | Cost per Filter (Commercial) | Total Project Cost Range | Installation Cost Range (Specialized Environments) |

|---|---|---|---|

HEPA | $10 - $50 | $500 - $5,000 | $300 - $5,000 |

ULPA filters use more energy because they block air more. This means you pay more for power and fixing them. If you want to save money and still have clean air, HEPA filters are a good choice for most uses.

When you choose a filter, match it to your system and needs. First, check what size particles you want to remove. For small bits, use HEPA, membrane, or ULPA filter paper. For fast cleaning, pick coarse or glass fiber filter paper. For hot places, glass fiber filter paper works best.

Make sure your filter fits your air system. Check airflow and pressure drop so your system does not get overloaded. Use pre-filters like gradient filter paper to catch big particles first. This helps your main filter last longer. Make sure your system seals well to stop leaks.

Companies like MECONM New Materials have many filter choices. You can pick the pore size, thickness, and fiber mix you need. For example, MB3831HT HEPA filter paper works in hot places and clean rooms for medicine. If you need help, MECONM can help you pick or design the right filter.

Note: Always follow what the maker says for changing and caring for filters. This keeps your air clean and your system working well.

If you want to know more about filter materials, you can look at MECONM’s air filter paper, membrane filter paper, and gradient filter paper. Their team can help you pick and customize filters for any place, from labs to chip factories and very clean rooms.

You should pick a filter that fits your needs. HEPA filters are good for most cleanrooms and cost less money. ULPA filters catch even smaller bits but use more energy and cost more. Here is a checklist to help you choose:

Criteria | HEPA Filters | ULPA Filters |

|---|---|---|

Filtration | 99.97% ≥ 0.3μm | 99.9995% ≥ 0.12μm |

Airflow | Lower resistance | Higher resistance |

Cost | Lower | Higher |

Lifespan | Up to 10 years | 7-8 years |

Best for | Most cleanrooms | Stricter cleanrooms |

Pick trusted companies like MECONM for air filter paper or membrane filter paper. This helps you get the best results.

HEPA filters trap 99.97% of particles at 0.3 microns. ULPA filters catch 99.999% of particles down to 0.12 microns. You should choose based on how clean you need your air.

You should check the size of particles you want to remove. For most cleanrooms, HEPA filter paper works well. For stricter environments, use ULPA filter paper. MECONM offers both types and can help you select the right air filter paper.

You should replace HEPA filters every 12 months in HVAC systems. ULPA filters need changing every 6 months. In cleanrooms, HEPA filters last up to 10 years, while ULPA filters last about 7 to 8 years.

Yes! MECONM air filter paper and hydraulic oil filter paper work in many fields. You can use them in electronics, pharmaceuticals, automotive, and farming. Their filter materials meet high standards for clean air and safety.